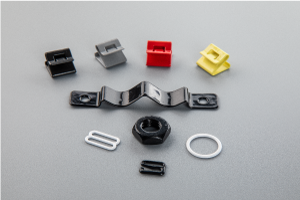

Manufacture process start with dip the preheated mould in vinyl chloride paste, slowly pull up vinyl chloride will adhere at the surface of mould. after that heat it in the furnace the condition of sol will transform to gel. Then let it cool and remove. Cutting process is the last process before finishing the products.

Manufacture process starts with dip the preheated mould in vinyl chloride paste, slowly pull up vinyl chloride will adhere at the surface of mould. After that, heat it in the furnace the condition of sol will transform to gel. Then let it cool and remove. Finishing Process for PVC Sol is the last process before finishing the products. This process is for PVC insulation, car and motorcycle battery poles, and electrical control cabinet insulator.

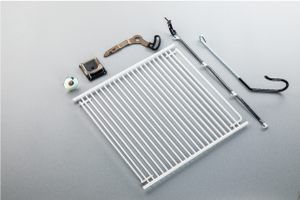

Dip Coating to cover metal with plastic. The metal, usually in rod formis heated in an oven until it is hot, then dipped into a container of plastic powder or sol, the plastic melts onto the metal and sticks to it. The coated metal is put back into the oven until the plastic becomes smooth and shiny then removed and left to cool. Corrosion.

Dip Coating to cover metal with plastic. The metal, usually in rod form is heated in an oven until it is hot, then dipped into a container of plastic powder or sol, the plastic melts onto the metal and sticks to it. The coated metal is put back into the oven until the plastic becomes smooth and shiny then removed and left to cool. Corrosion. Main raw materials of this process are PVC, PA, PE, PP.

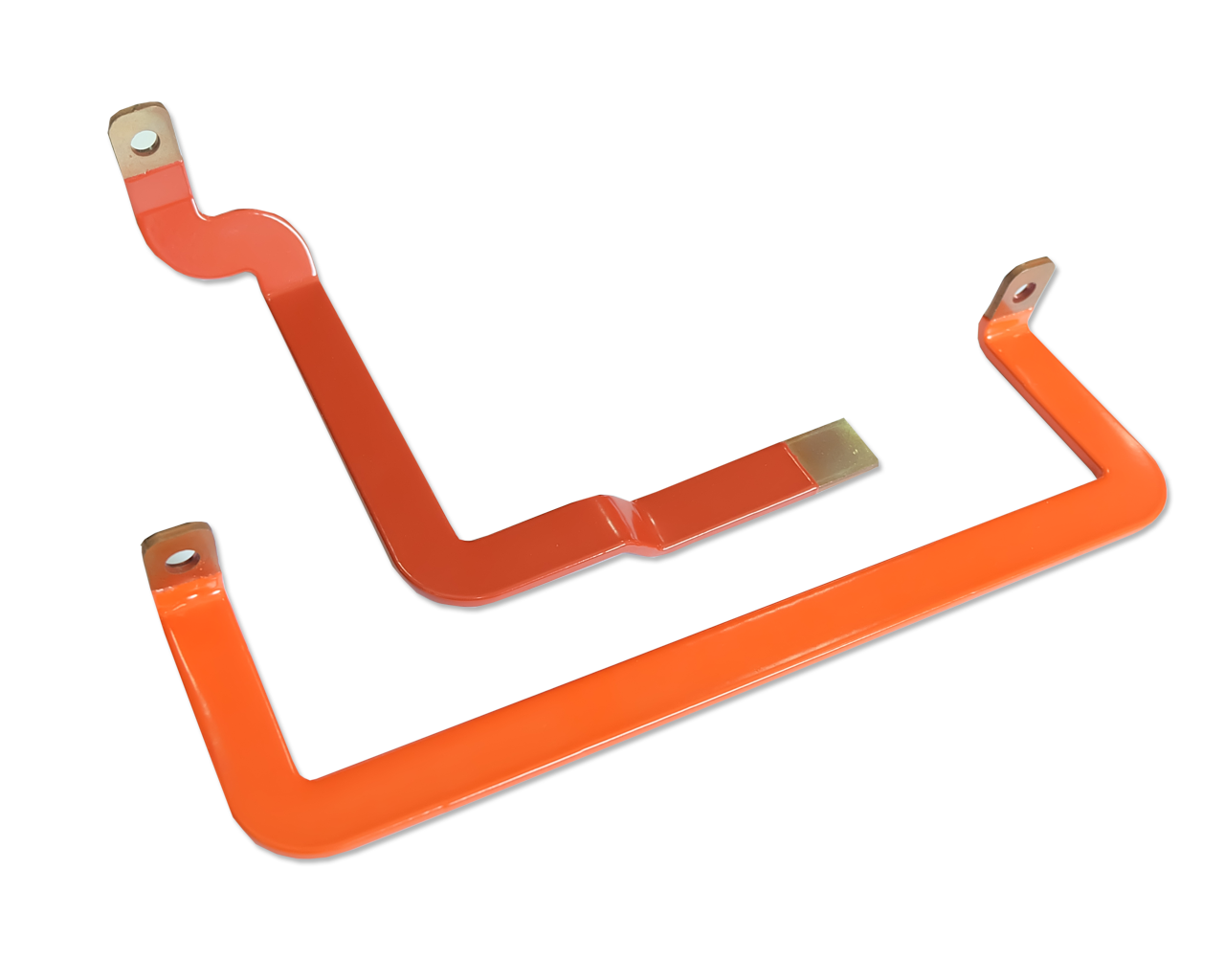

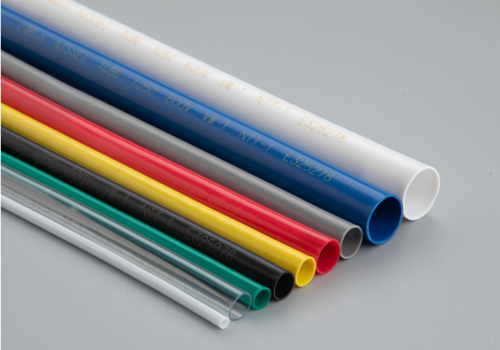

Extrusion products for the automotive and Electrical insulation of components devices. Excellent heat aging, insulation, incombustibility and Electrically insulating tube with a performance based on customer requirement standards. Control and Test follow up JIS Japanese Standards Association.

Extrusion products for the automotive and Electrical insulation of components devices. Excellent heat aging, insulation, incombustibility and Electrically insulating tube with a performance based on customer requirement standards. We also produce PPU and Nylon Tube, and other medical supplies and equipments, EV car and accessories.

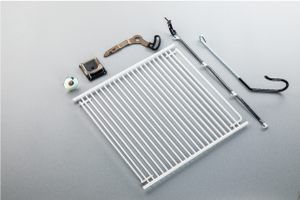

The product for Electronic part, Automotive part, Medical components, agricultural machinery and EV car. Raw material of this method are ABS, POM, PC, PVC, PA, Elastomer etc.

In addition to this, NISSEI offers a diverse range of top-quality products that encompass both innovation and meticulous development, ensuring the highest level of quality. These products are designed to meet the demands of the industry and general users to the greatest extent possible.

We also serve any other customers requirements to meet their satisfaction. Most of these are products that are used in the automotive and electronics industries.